Innova’s Black Buffalo team are Redefining Future of 3D Construction by delivering the World's No1. projects in terms of design and Quality

Our 3D printing leadership ensures every build is robust, sustainable, and harmonious with its surroundings and the people that live and work in them. Innova Living pioneers the future of construction with our visionary designs and interior aesthetics that elevate the human experience. Our commitment to sustainability and efficiency is matched only by our dedication to innovation in design. We’re on a mission to build with a purpos incorporating form and function using state-of-the-art technologies, including automation, robotics, and intelligent design, to construct exceptional retirement resorts, vibrant residential communities, and dynamic commercial spaces.

Advanced 3D Printing Technology

NEXCON 3D Printers take the best characteristics of 3D printing and address many of the challenges found in the construction industry. The result is the ability to print structures remotely or on-site efficiently at a lower cost with greater sustainability.

Print Versatility

Ability to print onsite and custom designs. BB3D's state of the art construction technology is capable of printing up to 3 stories with 1,600+ square feet on each level.Material Versatility

With ICC-ES approved materials, our 3D's cement-based “printer ink” is formulated to be resilient, withstand harsh climates, structural, and stronger than a block wall.Cost Versatility

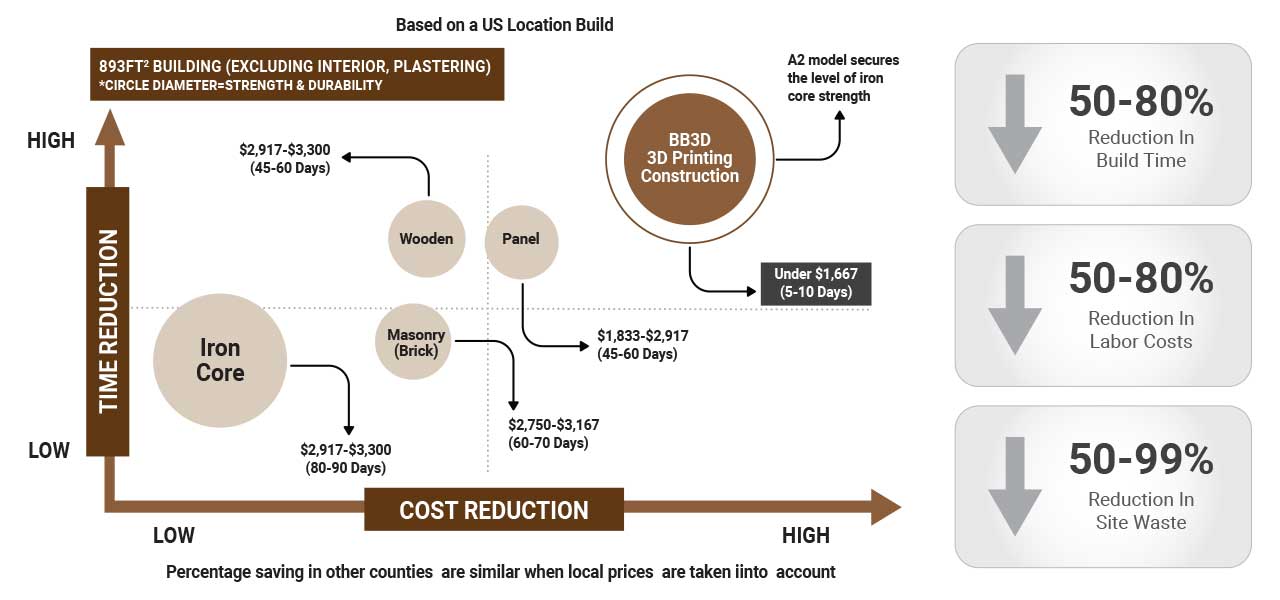

By reducing material use and project timelines, Black Buffalo 3d printed walls can be designed to meet project needs based on budget, energy efficiency goals, and overall function.Time & Cost

Rapid Construction Time: Utilizing 3D construction technology, projects are completed faster, reducing exposure to harsh weather conditions and enhancing safety and productivity.

- Labor Benefits: 3D digital design to physical 3D construction eliminates onsite mistakes, automates manual labor, increases worker safety and reduces project timelines.

- Energy Efficiency: High-performance insulation and precise 3D printing reduce energy consumption and costs.

- Minimized Waste: Precision in 3D printing eliminates material waste, optimizing resource use.

- Labor Costs: A smaller workforce and reduced on-site labor translate to lower labor costs.

- Operational Savings: Superior insulation, stronger materials, and energy-efficient designs lower long-term operational costs.

- Customized Solutions: Tailored solutions for hot climates optimize building orientation, natural cooling techniques, and material selection, ensuring cost-effective project implementation.

- Construction Recruitment: Rapid 3D construction maximizes utility, and attracts a workforce interested in skilled, less physically demanding roles, creating opportunities in programming, machine operation, and maintenance, improving job satisfaction and productivity.

- Safety Benefits: A guided programmed print path reduces the risk of accidents and injuries. Controlled environment fabrication and continuous monitoring provide safer working conditions.

Material Durability

Rapid Construction Time: Utilizing 3D construction technology, projects are completed faster, reducing exposure to harsh weather conditions and enhancing safety and productivity.

- Material Durability: High-performance materials are designed to print continuously, cure quickly, and withstand extreme temperatures, ensuring the longevity and stability of structures.

- Design Flexibility: Innovative designs incorporating natural cooling and shading features reduce reliance on artificial systems, enhancing the durability of the building.

- Reduced Heat Island Effect: Integration of green roofs and reflective materials reduces heat absorption, promoting cooler environments and extending the lifespan of structures.

- Improved Air Quality: Precise ventilation systems ensure better airflow and air quality within buildings, contributing to the durability of the internal environment.

Raw Materials

Rapid Construction Time: Utilizing 3D construction technology, projects are completed faster, reducing exposure to harsh weather conditions and enhancing safety and productivity.

3D PRINTER INK

Developed through extensive research, development, testing trial and error, our proprietary ink mixture was the first to meet ICC-ES AC509 criteria for printing structural walls. It is an advanced dry mix created for 3D with excellent strength, interlayer bonding, and durability.

CLIMATE CONDITIONS

Our proprietary ink mixture can be manufactured locally and customized to use locally available ingredients while retaining properties of our ICC-ES approved formula.

ADDITIVES

Our proprietary print ready ink has additives, fibers, and supplementary cementitious materials already included to it can be stored dry and is ready to print by just adding water onsite.

PROPRIETARY BLENDS

Unique ink formulas are exclusive to Black Buffalo 3D and have undergone extensive in–house, partner level, and internationally recognized ICC-ES testing to exceed traditional requirements for building

Eco-Friendly

- Sustainable Materials Supply & Consulting: High-performance, eco-friendly 3D ink materials tailored for 3D printing and expert design advisement to optimize projects for sustainability and efficiency.

- Sustainability: The use of eco-friendly materials and methods minimizes the environmental impact, promoting energy efficiency and reducing the carbon footprint.

- Thermal Efficiency: Better insulation keeps interiors cooler, reducing energy consumption and costs.

- Reduced Heat Island Effect: Eco-friendly strategies such as green roofs and reflective materials help reduce heat absorption and promote cooler environments.

Traditional Build Methods Result in 30% Waste

Traditional construction methods are not only labor-intensive but also result in significant material waste. On average, 30% of materials are wasted in conventional building projects, contributing to higher costs and environmental impact.

Enhanced Resilience with 3D Construction - "Building Resilient Homes for a Resilient Future."

Our 3D constructed developments are more resilient because:

- Advanced Materials: Use of high-performance, durable materials that withstand extreme weather conditions and natural disasters.

- Precision Engineering: 3D printing allows for exact specifications, reducing structural vulnerabilities and ensuring consistent quality.

- Integrated Design: Customizable features that enhance structural integrity and durability, such as reinforced walls and optimized load-bearing capabilities.

- Sustainability: Eco-friendly materials and construction practices that reduce environmental impact and improve long-term sustainability.

- From Drawing to Reality: The Benefits of Our Design Team - "Turning Vision into Reality with Precision and Expertise."

Our design team is dedicated to bringing your vision to life with harmony and design aesthetics that touch the human spirit.

- Evoking Human Senses with Our Designs: We create environments that not only look beautiful but also evoke emotional and sensory experiences, ensuring each space resonates deeply with its inhabitants.

- Holistic Design Services: From concept to construction, we offer comprehensive guidance, ensuring your project resonates with personal preferences and environmental synergy.

- Collaborative Expertise: Our architects, engineers, and material scientists collaborate to reflect your vision in a design that embodies balance and beauty.

- Precision Technology: With advanced 3D modeling, we visualize and refine your project for flawless execution, minimizing errors and revisions.

- Innovative Efficiency: We streamline the design process for cost-effectiveness and timely delivery, integrating cutting-edge 3D construction technology for superior sustainability and quality.